Differential Pressure Gauge MK5 - DN100

Fields of application

- Indication of pressure drops in filter

- Level indication in closed or open tanks

- Flow measurement in gasses and fluids

Specifications

Differential Pressure Gauge MK5 - DN100

These differential pressure gauges were conceived with a special view to protecting the gauges against over pressure i operation and to eliminate the effects of operator errors during engagement and disengagement.

The measuring system consist of a single diaphragm with the high and low pressures being applied in the measuring chamber on each side of this diaphragm. The differential pressure is available as a single pointer read out on the large 270° dial. A set of calibration springs take up the resulting forces of the diaphragm and decide the displacement of the diaphragm in relation to the differential pressure.

Beyond the maximum limit for the displacement of the diaphragm it is fully supported by the specially machined measuring chamber thus allowing a one sided load on the gauge up to the full static pressure with no detrimental effect to the calibration and accuracy of the gauge.

The displacement of the diaphragm is converted into an angular displacement through a torsional shaft taken through the wall of the measuring shaft with negligible friction. The rotation of the shaft is transmitted through the movement of the gauge to the pointer.

The construction of the measuring system makes it unnecessary to fit an equalizing valve to protect the gauge. However, if a continuous check on the ZEPO must be maintained, it is still necessary to fit stop valves and an equalizing valve, but as the sequence of valve operations is not critical it is unnecessary to fit expensive fool proof valve units.

Standard articles

Click on the article to automatically insert into the contact form below

To view our standard articles please visit from a desktop

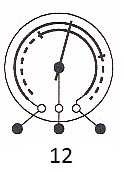

Single contact

(1 contact point)

Avaliable contact types:

KN,KM,KE and KI

Contact Function : Break

1

Contact Function : Close

2

Contact Function : Shift

3

Contact Function Separate Circuits : Break

4

Contact Function Separate Circuits : Close

5

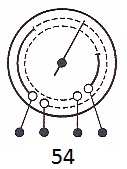

Double contact

(2 contact points)

Avaliable contact types:

KN,KM,KE and KI

Shift contact

(2 contact points switch function)

Avaliable contact types:

KN and KM

Double contact

(2 contact pointers seperate Circuits)

Avaliable contact types:

KN and KM

Triple contact

(3 contact pointers)

Avaliable contact types:

KN and KM

Triple contact

(3 contact pointers)

Avaliable contact types:

KN and KM

Do you need assistance?

Vi står altid til rådighed til at hjælpe dig, uanset hvilke spørgsmål du måtte have. Tøv ikke med at kontakte os gennem kontaktformularen, eller find din kontaktperson her

.png)